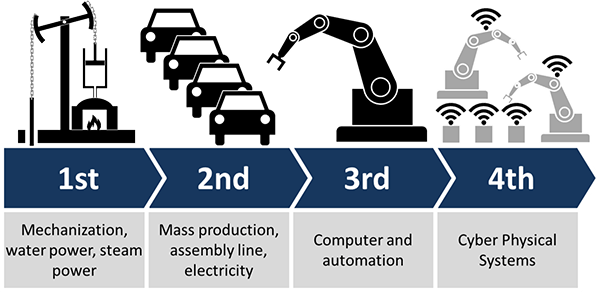

The third industrial revolution, the “digital revolution,” started with the computer age in the mid-20th century and ultimately set off the information age that has probably defined most of your life. We’ve basically been making variations on the same themes the whole time, though: we build increasingly complex computing systems, automate a few more processes, and find creative new ways to waste time on the Internet. It’s about time for a new revolution.

Industry 4.0, the fourth installment in the story of human industrial progress, is all about making things smarter. The leap from three to four isn’t so much a physical change as it is a cyber-physical one. Cheap, low-powered sensors embedded in machines and devices can generate huge amounts of information that can then be processed, analyzed, shared, and acted upon – mostly without human intervention. Basically, computers are crossing the gap from cyberspace to meatspace, and they’re self-optimizing. Welcome to Industry 4.0, where the Internet has more things than people, and the things can more or less take care of themselves.

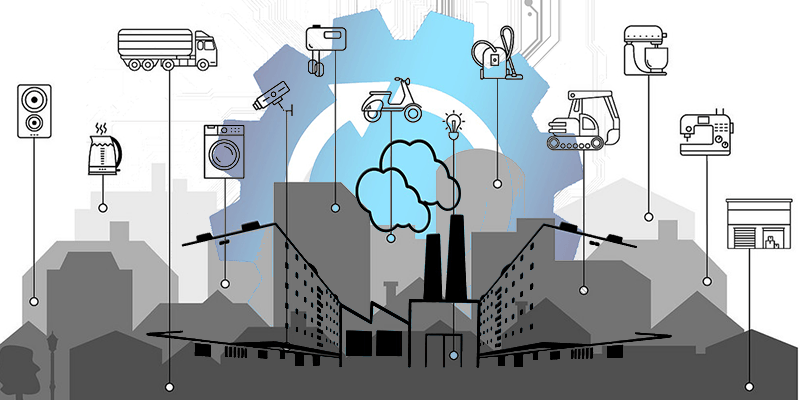

Where it begins: the Industrial Internet of Things

The IIoT, or Industrial Internet of Things, is fairly similar to the IoT most consumers already know and love. In its current form, it’s mostly networks of sensors generating data that can be analyzed and used for whatever humans need to do: identify inefficiencies, estimate when a machine might need maintenance, track performance, etc.

On the hardware side these sensors are fairly basic, and many of them are found in consumer devices as well: temperature, proximity, optical, infrared, location, smoke, etc. They can be found in everything from robots trawling around warehouse floors to the tablets human workers use to monitor the other sensors. Basically, they just detect the state of a device and either send that data to a hub for processing or process it locally.

What’s changing is how the hardware is connected and where it’s sending the data: the sensors are often part of large mesh networks in contact with local hubs and/or each other. This is important since smart factories don’t just want to generate data for later analysis; they want data that can be used in real time. The ultimate goal of Industry 4.0 is to have everything connected to everything else, with factory sensor data working alongside data from external sources to optimize operations. This is the real challenge: what do you do with all the data?

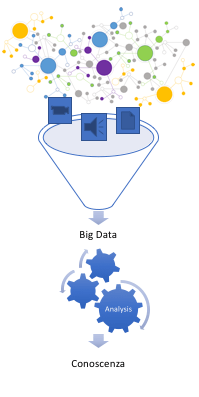

Big data, big changes

The term “big data” is often misunderstood as “having a lot of data.” That’s partially true, but the real reason that big data is exciting, and the reason that we’re trying to generate more of it, is because we now have the ability to really put it to use. In other words, the “big” refers more to the amount of data that we can process than the amount of data that we have. Being able to make sense of vast datasets is the real power behind Industry 4.0. Take the idea of predictive maintenance, for example:

- A factory puts sensors on a lot of its manufacturing machines, constantly generating visual, thermal, and even data about air quality.

- The sensors feed data about the machines’ performance to an AI, building up a trove of historical data.

- After a few maintenance cycles and machine failures, the AI can compare real-time data with historical data to predict when a machine is wearing down.

- After that, you have “predictive maintenance” – the ability to anticipate failure and initiate maintenance processes without anyone needing to examine the machine or, worse, the machine displaying visible signs of failure.

- Eventually, the AI will simply be able to dispatch robots to fix the machine, only involving humans if there’s an exception.

- The data can even be used in the future to upgrade the machine or create a new one that works more efficiently, designed and built at least in part by the AI itself.

That’s just one example. Effectively analyzing and using these unstructured oceans of sensor data can help optimize shipping, improve safety, prevent failures, react to changes in supply and demand, and even identify new opportunities and insights, all in real time.

Ultimately, the sensors, AI, and physical hardware will be integrated into an ecosystem that can essentially make its own decisions, implement them, and optimize operations without direct human action. A smart factory will still have humans, of course, but they’ll largely be exception-handlers whose main job is to take care of the more abstract jobs using the information delivered to them by the machines. It’s impossible to predict the exact impacts that an event as broad as an industrial revolution will have, but the role of humans certainly won’t be the same.

Issues with IIoT/Industry 4.0

If you thought data breaches were bad before, imagine what cybersecurity issues could do to IoT-filled smart factories. An electronic attack could disrupt a lot of physical activity, whether it’s just stopping assembly lines, damaging machines, or even killing people. It’s pretty vital that as our devices get smarter, so does our security.

Ideally, this will go hand in hand with measures to protect privacy and promote transparency as well. Smart factories won’t just be getting data from machines, they’ll be getting it from users as well, either directly or indirectly. IoT is integrating itself into human life, and Industry 4.0 is hungry for data. It’s good for everyone if user data can optimize operations, but there need to be steps taken to ensure user control and anonymity throughout the process. Nobody wants their every move, heartbeat, and Amazon purchase to be accessible in real time through an interface somewhere.

Getting cyber-physical

Consumer devices are already generating a lot of data that companies are using to make decisions, and whether users like it or not, this data collection is likely to become even more prevalent and detailed in the future. As factories get smarter, so will the research labs, companies, and supply chains that ultimately put things into consumers’ hands. Smart homes, smart cars, smart phones, and smart factories will be different facets of an increasingly-automated ecosystem that, for better or for worse, knows what we want and knows how to get it to us most efficiently. Either way, Industry 4.0 is here, it’s jam-packed with sensors and data, and it wants to connect, predict, and optimize everything it can.

Image credits: Microsoft Azure Sphere OS (Linux kernel), Industry 4.0