One of the most significant pain points of IoT is battery life. For as long as wearable tech has existed, researchers and enterprises have been searching for new ways to not only prolong the battery life of wearable tech but find sustainable, effective ways to harvest energy.

A new human-machine interface has emerged, which sounds like something out of science fiction: energy harvesting. It’s a combination of engineering, nanomedicine, flexible electronics, and energy storage advancements. What makes it even more impressive is the amount of R&D required. It’s not just testing new theses but often creating technology from scratch, such as new kinds of sensors and electronic skin, to make scientific inquiries possible in the first place.

Combinatorial wearable innovation: sweat and motion

Researchers have long been interested in using the body to harvest energy, ideally to replace or supplement battery power. This includes research into the creation of energy-harvesting boots that gain energy through walking and hearable tech powered by jaw movements. However, typically body-generated energy generated doesn’t produce enough power to be effective. This week nanoengineers at the Center for Wearable Sensors at UC San Diego shared a “wearable microgrid” that harvests and stores energy from the human body to power small electronics.

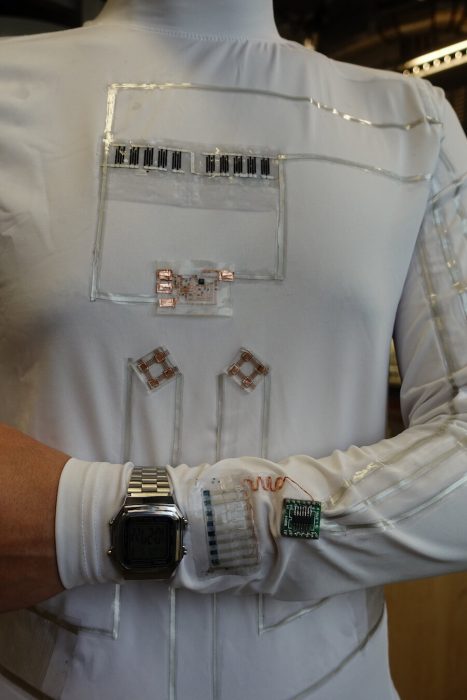

Harvesting energy from both movement and sweat enables the wearable microgrid to power devices quickly and continuously. The triboelectric generators provide power as soon as the wearer starts moving, before breaking a sweat. Once the user starts sweating, the biofuel cells start providing power and continue to do so after the user stops moving.

Biofuel cells that harvest energy from sweat are located inside the shirt at the chest. Emblems called triboelectric generators on the shirt convert energy from movement into electricity. They harvest energy from the swinging movement of the arms against the torso while walking or running. Supercapacitors outside the shirt on the chest temporarily store energy from both devices and then discharge it to power small electronics.

The researchers are also working on other designs that can harvest energy while the user is sitting inside an office, for example, or moving slowly outside.

Biofuel cells and electronic skin

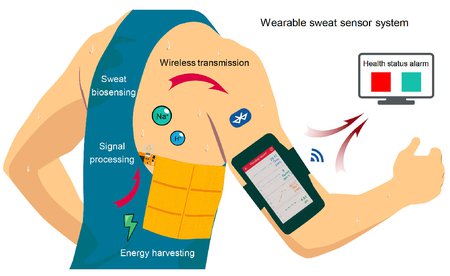

Wei Gao, assistant professor in the Andrew and Peggy Cherng Department of Medical Engineering at Caltech, has developed an electronic skin, or e-skin, that is applied on top of your real skin. It’s made from soft, flexible rubber and can be embedded with sensors that monitor information like heart rate, body temperature, blood sugar levels and metabolic byproducts that are indicators of health, and even the nerve signals that control muscles. The e-skin runs on biofuel cells without the need for batteries.

A thin sandwich of Teflon, copper, and polyimide attaches to the skin. As the person moves, these sheets of material rub against a sliding layer made of copper and polyimide and generate small amounts of electricity. The effect, known as triboelectricity, is likened to receiving a static electric shock from walking across a carpeted floor and then touching a metal doorknob.

Wei Gao told CalTech that human sweat contains high levels of the chemical lactate, a compound generated by muscles during exercise. The fuel cells built into the e-skin absorb that lactate and combine it with oxygen from the atmosphere, generating water and pyruvate, another by-product of metabolism. As they operate, the biofuel cells generate enough electricity to power sensors and a Bluetooth device similar to the one that connects your phone to your car stereo, allowing the e-skin to transmit readings from its sensors wirelessly.

Thermal energy powering wearable tech

One of the earliest commercial offerings using energy generated by the wearer i is the MATRIX PowerWatch series. They are a range of smartwatches which use thermoelectric energy (otherwise known as the Seebeck Effect), converting low-grade heat from a person’s body to power a smartwatch.

MATRIX redesigned the TEG’s nanostructure material to optimize for high-performance with low thermal conductivity and high electrical conductivity. The result: a solid-state module that is three times more efficient than other thermoelectric solutions.

However, energy-harvesting wearables historically suffer from the low level of energy generated and its low power storage capacity, limiting its effectiveness, particularly in thermoelectric materials. The watches come without chargers, although more recent versions have included solar charging, highlighting the difficulty of generating enough energy for extended periods of time and as the company added more features. The functions of the watch include smartphone notifications, calorie counting, GPS, steps counting, and a sleep tracker.

Kinetic energy harvesting

On a 72-hour mission, soldiers may carry up to 23.4lbs (10.6kg) of batteries to power communications, navigation, and optics equipment. This weight limits the range and speed of travel for soldiers. In response, Bionic power has created The PowerWalk® Kinetic Energy Harvester. It’s a wearable device that provides 10 to 12 watts of wearable, on-the-move power, reducing both mission costs and risks.

With every stride, the harvester’s onboard microprocessors analyze the wearer’s gait to determine when to generate the most power. The PowerWalk’s gearbox converts the knee’s rotational speed to a higher speed. A generator converts the mechanical power produced into electrical power. A power-conversion circuit then converts the electricity to recharge Li-ion or NiMH batteries.

Its creators estimate that on a typical duty day, the PowerWalk can save US$135 in batteries. With 200 mission days per year, the total cost savings are US$27,000 annually per soldier. The company currently has several contracts with the US Army, including a contract valued at $1.25 million from the Secretary of Defense’s Office to supply low-volume production units of its PowerWalk Kinetic Energy Harvester.

Vibrational Energy

Piezoelectricity has interested researchers since the 1880s. It refers to the application of mechanical stress to solid materials, such as crystals, ceramics, bone, and DNA to generate energy. It’s particularly interesting when it comes to subcutaneous wearable tech, such as pacemakers and other implants. Pacemakers last a decade before the body rejects the batteries. Researchers hope that implants such as pacemakers and cardioverter-defibrillators could one day be powered by energy harvested from repetitive motion inside the body, such as the heartbeat.

Materials innovation in wearable tech

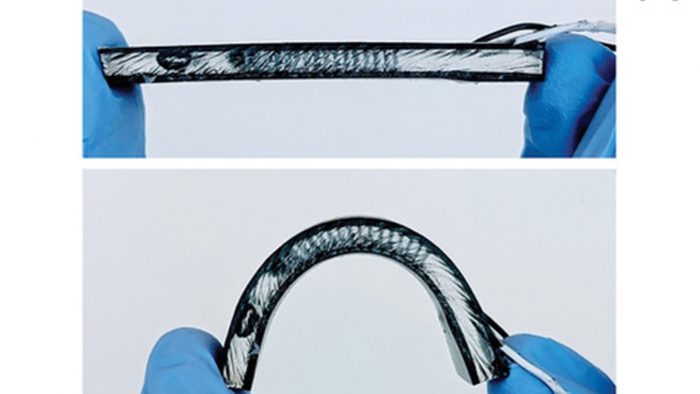

Since 2017, engineers at North Carolina State University have been working on a flexible body heat harvester. The harvesters use heat energy from the human body to power wearable technologies, as with the Matrix Power Watch. However, unlike the Power Watch, flexible harvesters have traditionally lagged behind rigid devices, which have been superior in their ability to convert body heat into usable energy. A new research report released this month reports significant enhancements in preventing heat leakage in the flexible body heat harvester.

According to Dr. Ozturk, NC State professor of electrical and computer engineering, the e-skin employs the same semiconductor elements used in rigid devices perfected after decades of research. The approach also provides a low-cost opportunity to existing rigid thermoelectric module manufacturers to enter the flexible thermoelectric market.

As with other wearable tech, much of the commercial focus of energy harvesting technology focuses on athletes and the military. It’ll be a while before we can buy wearable tech that harvests enough energy to power more than low-power devices. But there’s plenty to keep researchers occupied.